When it comes to cutting large pieces of material, especially wood, two of the most popular tools are the track saw and the table saw. Both are essential in a workshop, yet they serve distinct purposes and are designed for different types of projects. Understanding the differences between these two tools will help you select the best saw for your needs, whether you’re working on cabinetry, furniture, or simply DIY projects.

In this article, we’ll explore the unique functions, capabilities, and applications of track saws and table saws, providing an in-depth comparison to help you make an informed choice.

Quick Introduction to Track Saw and Table Saw

Track Saw

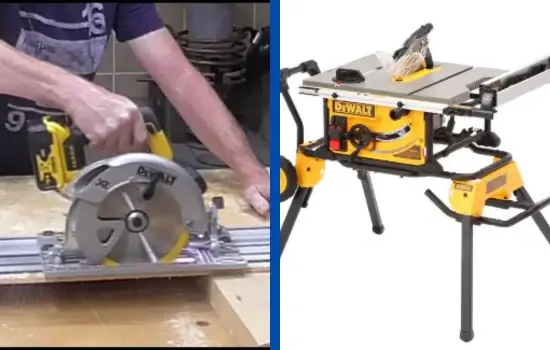

A track saw is a circular saw that moves along a straight track or rail. This design enables precise, clean, straight cuts on large materials without the need to move the material itself. Track saws are portable and can make rip cuts, crosscuts, and even angled cuts, providing great flexibility for projects that require large panels or precise cuts.

Table Saw

A table saw is a powerful tool with a circular blade mounted under a flat tabletop. It’s ideal for making long, straight cuts (rip cuts) and precise crosscuts on a variety of materials. Unlike a track saw, which moves along a guide rail, the table saw’s blade remains stationary, and the material is pushed through the blade. Table saws are staples in most workshops due to their power and versatility.

Key Differences Between Track Saw and Table Saw

| Feature | Track Saw | Table Saw |

|---|---|---|

| Primary Function | Precision cutting on large panels | Rip cuts, crosscuts, and general woodcutting |

| Cutting Motion | Saw moves along a track | Material is fed into a stationary blade |

| Portability | High, lightweight and easy to move | Low, generally stationary or on a mobile base |

| Cutting Accuracy | High, excellent for straight, precise cuts | High, especially for rip cuts and crosscuts |

| Cutting Capacity | Limited by track length | Limited by rip fence distance and table size |

| Safety Features | Blade guard, anti-kickback mechanism | Blade guard, riving knife, anti-kickback pawls |

| Dust Collection | Excellent when paired with a dust extractor | Usually effective, but varies by model |

| Applications | Breaking down sheet goods, cabinetry | Woodworking, furniture-making, joinery |

| Cost | Mid-range to high | Mid-range to high, depending on features |

Detailed Comparison of Track Saw and Table Saw

1. Primary Purpose and Cutting Capabilities

- Track Saw: A track saw is ideal for making precise, straight cuts on large materials like plywood sheets, MDF, and other panel products. The saw rides along a guide rail, ensuring a smooth, straight cut without the need for a large workspace. Because of its design, a track saw is especially useful for breaking down large sheets in a limited space. Track saws can also make angled cuts, making them versatile for various applications, including cabinetry and carpentry.

- Table Saw: The table saw is designed for rip cuts and crosscuts, making it highly versatile for various woodworking projects. It’s great for long, straight cuts, and with accessories like a miter gauge and fence, it can perform accurate crosscuts and bevel cuts. Table saws are staples in most workshops due to their ability to handle a wide variety of materials and cut types, from thick wood to plywood sheets.

2. Cutting Motion and Material Handling

- Track Saw: In a track saw, the blade moves along a track that you place on the material you want to cut. This allows you to keep the material stationary, which is particularly useful for cutting large sheets. The guide rail or track ensures precision, and since you’re bringing the saw to the material, it’s ideal for situations where maneuvering large boards or sheets would be difficult.

- Table Saw: In contrast, the table saw requires the material to be fed into the stationary blade. The material is guided along the rip fence or miter gauge, making it easy to maintain straight and precise cuts, especially on narrower pieces. However, this setup requires a larger workspace and makes handling large, unwieldy sheets challenging.

3. Portability and Workspace Requirements

- Track Saw: Track saws are highly portable and can be used on-site or in a workshop. Since they’re designed to work on top of the material, they don’t require much space or a dedicated work area. This portability makes track saws suitable for contractors, carpenters, and DIY enthusiasts who need to transport their tools frequently or work in tight spaces.

- Table Saw: Table saws are generally stationary tools, especially cabinet models, which require a dedicated workspace. While some job-site table saws are portable, they’re still bulkier than track saws and require a stable surface. Their large footprint makes them better suited to fixed workshop environments, where they can remain set up and ready for various tasks.

4. Cutting Accuracy and Precision

- Track Saw: Track saws excel in precision, especially for straight cuts on large panels. The guide rail ensures accuracy and prevents drift, allowing for smooth, clean cuts with minimal tear-out. Track saws are particularly useful for applications where exact dimensions are crucial, such as in cabinetry and finish work.

- Table Saw: Table saws are also highly accurate, especially for rip cuts, as the material is guided by the fence. With additional accessories like a miter gauge, they can also perform precise crosscuts. However, achieving high accuracy requires careful setup and alignment, particularly for large or complex cuts. The stationary blade and controlled feed rate contribute to the table saw’s precision, making it ideal for repeatable cuts.

5. Cutting Capacity and Versatility

- Track Saw: The track saw’s cutting capacity is limited by the length of the track. For example, a standard 4-foot track will only allow cuts up to 4 feet in length. However, some systems have extensions or longer tracks for larger projects. Track saws are versatile for breaking down large panels and making plunge cuts, but they may struggle with thick materials that require a more powerful saw.

- Table Saw: The cutting capacity of a table saw is primarily limited by the width of the table and the rip fence’s distance from the blade. Most table saws can cut wider boards than a track saw without the need for additional accessories. A table saw’s versatility is enhanced by its ability to perform multiple types of cuts—rip cuts, crosscuts, bevel cuts, and even dados (with an appropriate dado blade set)—making it a multifunctional tool in a woodworking shop.

6. Safety Features

- Track Saw: Track saws have several safety features, including blade guards and anti-kickback mechanisms. The track also helps prevent accidental drift, which reduces the risk of kickback. Track saws are generally safer for cutting large panels, as the material remains stationary and only the saw moves, minimizing the risk of mishandling or accidental contact with the blade.

- Table Saw: Table saws are equipped with various safety features, such as a blade guard, riving knife, and anti-kickback pawls, which reduce the risk of kickback. However, table saws require users to push the material through the blade, increasing the risk of accidental contact. It’s essential to use push sticks, push blocks, and maintain proper positioning when operating a table saw, especially when cutting narrow or small pieces.

7. Dust Collection

- Track Saw: Track saws are typically paired with a dust extraction system that attaches directly to the saw, allowing for efficient dust collection. This setup is particularly beneficial for indoor work, where minimizing airborne dust is crucial. Track saws excel in dust management, especially when cutting MDF and plywood, which produce fine dust particles.

- Table Saw: Most table saws have a dust collection port, though the effectiveness varies by model. Cabinet table saws generally offer better dust collection than portable models, as they enclose the blade in a cabinet that funnels dust to the collection port. However, dust management can be a challenge with table saws, particularly for outdoor or job-site models.

8. Cost Considerations

- Track Saw: Track saws range in price, with high-quality models from brands like Festool, Makita, and DeWalt costing more due to their accuracy, build quality, and features. They’re generally considered mid-range to high in terms of price, especially when buying longer or additional tracks for extended cutting capabilities.

- Table Saw: Table saws also vary in price, with benchtop models being more affordable and professional-grade cabinet saws being significantly more expensive. Entry-level table saws are often budget-friendly, but quality and precision tend to improve with more expensive models. A high-end table saw can be a considerable investment, especially when factoring in additional accessories.

Pros and Cons of Track Saw and Table Saw

Track Saw Pros:

- Highly portable and easy to set up on-site

- Ideal for straight, precise cuts on large panels

- Effective dust collection when paired with an extractor

- Safe for cutting large materials, as the material stays stationary

Track Saw Cons:

- Limited cutting capacity based on track length

- Less effective for repetitive cuts on smaller pieces

- Generally not suited for complex joinery or angled cuts beyond simple bevels

Table Saw Pros:

- Highly versatile, capable of rip cuts, crosscuts, bevels, and dados

- Excellent precision for repeatable cuts, especially with a stable fence

- Suitable for cutting thick and dense materials

- Durable and long-lasting, especially in a stationary workshop setup

Table Saw Cons:

- Less portable and requires a larger workspace

- Requires careful handling, especially with small or narrow cuts

- Dust collection can be less effective, particularly with portable models

Choosing Between a Track Saw and a Table Saw

Selecting the right tool between a track saw and a table saw depends on your specific needs:

- If your primary focus is on cutting large sheets and panels with precision and portability, a track saw is the ideal choice. It’s easy to use on-site, and the guide rail ensures straight, clean cuts without needing a dedicated work area.

- If you need a versatile tool for making a variety of cuts—especially rip cuts, crosscuts, and precise, repeatable cuts for furniture-making and cabinetry—a table saw will serve you better. Its power, accuracy, and cutting capacity make it essential in a woodworking shop, where a stable work surface and repeatable cuts are essential.

For many woodworkers, having both tools can be beneficial. A track saw’s portability and ease of handling large sheets complement the versatility and power of a table saw, creating a well-rounded workshop capable of tackling any project.

Conclusion

Both track saws and table saws have their unique advantages in woodworking and carpentry. By understanding their strengths and limitations, you can make an informed choice that aligns with your projects and workspace requirements. Whether you’re breaking down large panels or making precise cuts for joinery, the right tool will elevate the quality and efficiency of your work.