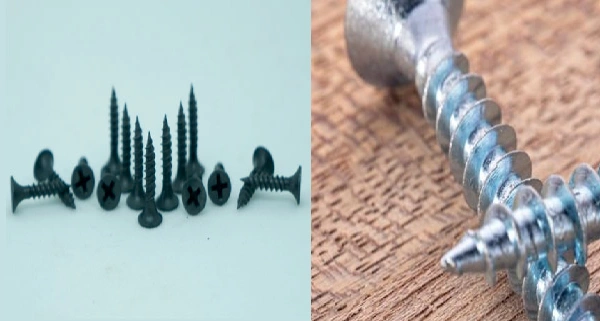

When tackling a home improvement or woodworking project, selecting the right screws is critical to achieving a sturdy, long-lasting result. Among the many options available, sheetrock screws (commonly known as drywall screws) and wood screws are two of the most commonly used fasteners. While they may look similar at first glance, these screws are specifically designed for different purposes.

This article will compare sheetrock screws and wood screws, including their characteristics, applications, advantages, and disadvantages, so you can choose the best fastener for your project.

What Are Sheetrock (Drywall) Screws?

Sheetrock screws are designed to fasten drywall (or sheetrock) to wood or metal studs. They are made of hardened steel and feature a fine or coarse thread, depending on their intended use.

Key Characteristics of Sheetrock Screws:

1. Material: Sheetrock screws are typically made from hardened steel and are often coated with black phosphate to resist corrosion.

2. Thread Design: Coarse-thread screws are used for attaching drywall to wood studs, while fine-thread screws are designed for metal studs.

3. Head Style: These screws have a bugle-shaped head, allowing them to countersink without tearing the drywall paper.

4. Length: Available in lengths ranging from 1 inch to 3 inches, depending on the thickness of the drywall and the material being fastened.

Common Uses for Sheetrock Screws:

- Securing drywall to wood or metal framing.

- Hanging ceiling drywall.

- Lightweight projects where structural strength is not a priority.

What Are Wood Screws?

Wood screws are specifically designed for woodworking projects, making them ideal for joining pieces of wood together. They are made from softer steel, brass, or stainless steel and come in a variety of sizes and head styles.

Key Characteristics of Wood Screws:

1. Material: Wood screws are often made of softer steel or corrosion-resistant materials like brass or stainless steel.

2. Thread Design: These screws have a coarse thread for gripping wood fibers and a smooth shank near the top to pull wooden pieces tightly together.

3. Head Style: Available in flat, round, or oval heads, depending on the application. Flat heads are the most common for flush finishes.

4. Length: Wood screws are available in a wide range of lengths and diameters, making them suitable for various woodworking tasks.

Common Uses for Wood Screws:

- Furniture construction and repair.

- Cabinetry and shelving.

- Framing and structural woodwork.

- Outdoor wood projects when treated or stainless screws are used.

Key Differences Between Sheetrock Screws and Wood Screws

| Feature | Sheetrock Screws (Drywall Screws) | Wood Screws |

|---|---|---|

| Material | Hardened steel with black phosphate coating | Softer steel, brass, or stainless steel |

| Thread Design | Fine or coarse threads; full-threaded | Coarse threads with a smooth shank |

| Head Style | Bugle head for countersinking | Flat, round, or oval heads for different finishes |

| Strength | Brittle, can snap under high torque | Durable, less prone to snapping |

| Primary Use | Securing drywall to studs | Joining wood pieces |

| Corrosion Resistance | Minimal (phosphate coating) | High (galvanized or stainless options) |

| Applications | Drywall installation | Structural and decorative woodworking |

Advantages of Sheetrock Screws

1. Specialized Design: The bugle head and thread design make sheetrock screws perfect for securing drywall without damaging the material.

2. Cost-Effective: Sheetrock screws are inexpensive and widely available, making them a budget-friendly option for drywall installation.

3. Lightweight: Their lightweight construction makes them easy to use in large quantities.

Disadvantages of Sheetrock Screws:

1. Brittle Material:

The hardened steel used in sheetrock screws is brittle, making them prone to snapping under high stress or torque.

2. Limited Applications:

They are not designed for heavy-duty or structural applications.

Advantages of Wood Screws

1. Versatility: Wood screws can be used for a wide range of woodworking projects, from furniture making to outdoor construction.

2. Durability: Made of softer, more ductile materials, wood screws can withstand greater torque without breaking.

3. Corrosion Resistance: Galvanized or stainless steel wood screws offer excellent resistance to rust, making them suitable for outdoor use.

Disadvantages of Wood Screws:

1. Cost: Wood screws are generally more expensive than sheetrock screws.

2. More Time-Consuming: The need for pre-drilling in certain types of wood can slow down the installation process.

Can You Use Sheetrock Screws for Woodworking?

While it may be tempting to use sheetrock screws for woodworking due to their low cost and availability, they are not recommended for structural or heavy-duty wood projects. Here’s why:

1. Brittleness: Sheetrock screws are made from hardened steel, which makes them brittle. They can snap under the pressure of heavy loads or when driven into dense wood.

2. Thread Design: The threads on sheetrock screws are not optimized for gripping wood fibers, resulting in weaker joints.

3. Corrosion Resistance: Most sheetrock screws are not corrosion-resistant and are unsuitable for outdoor or long-term use.

If you’re working on a woodworking project, it’s best to stick with wood screws for their durability and reliability.

When to Use Sheetrock Screws vs. Wood Screws

| Project Type | Recommended Screw |

|---|---|

| Drywall Installation | Sheetrock Screws |

| Furniture Making | Wood Screws |

| Framing or Load-Bearing Walls | Wood Screws |

| Cabinetry and Shelving | Wood Screws |

| Lightweight DIY Projects | Sheetrock Screws |

| Outdoor Wood Projects | Stainless Steel or Galvanized Wood Screws |

Conclusion

Both sheetrock screws and wood screws are essential tools for construction and DIY projects, but they are designed for very different purposes. Sheetrock screws are excellent for fastening drywall to studs and lightweight projects, while wood screws are better suited for woodworking and structural applications.

To ensure a successful project, always choose the screw that matches the material and load requirements. Using the wrong screw can lead to weakened joints, breakage, or even structural failure. With the right fastener, your project will be sturdy, reliable, and built to last.